Production Department

The Production Department consists of experienced and specialised technicians who, in combination with our advanced equipment, guarantee accuracy, speed, safety and reliability. Along with compliance to all technical standard and requirements.

With the continuous acquisition of new state-of-the-art machines and regular maintenance of the existing ones, all the manufacturing needs of the market are covered. In addition, the quality of project implementation is increased, the production time is reduced, and the quality of work is improved. Delivery time and maximum production efficiency is increased.

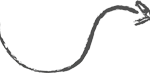

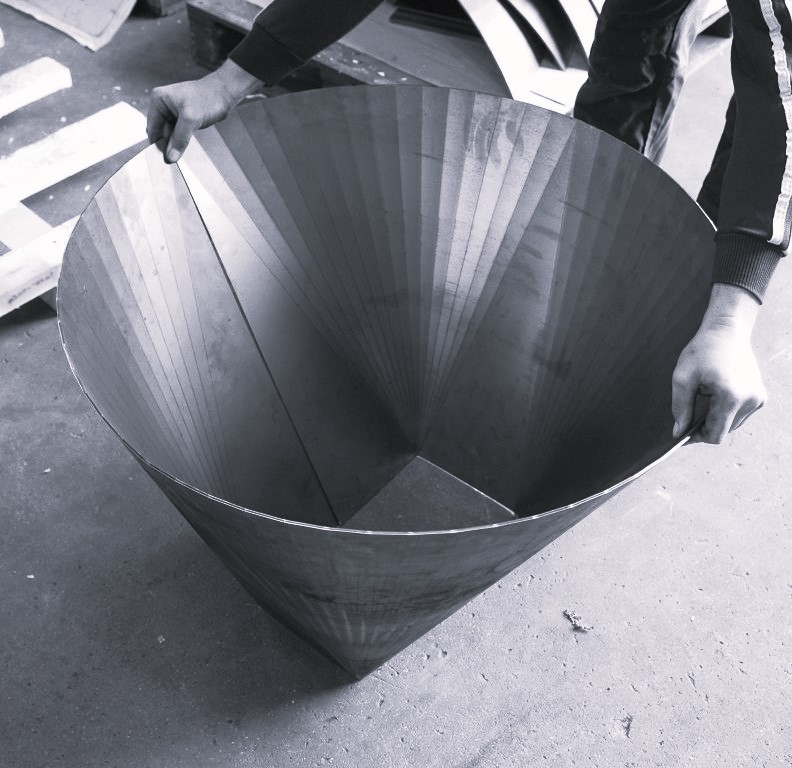

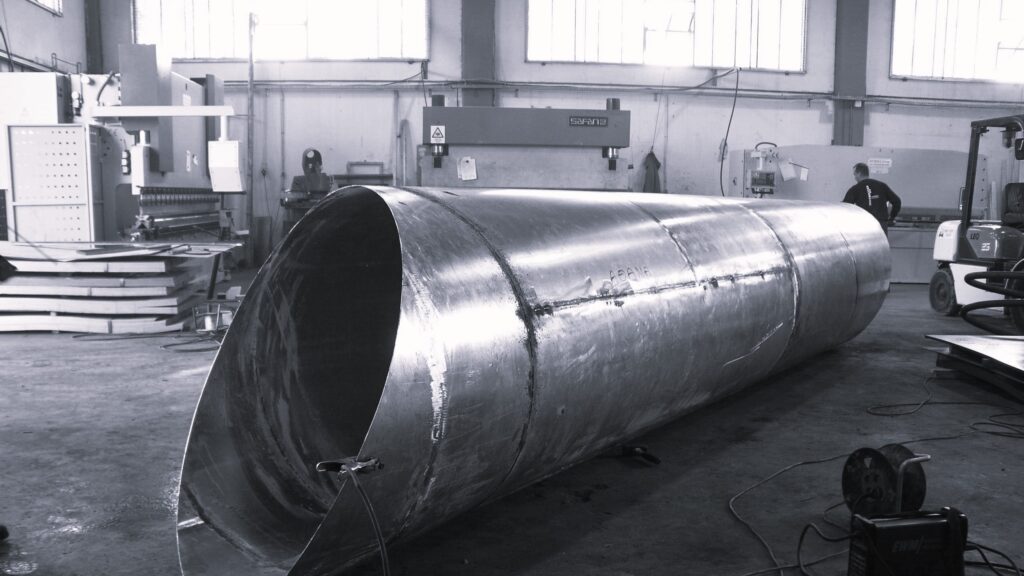

Our forming and welding machines meet the needs of our customers for high precision manufacturing. Our straddle carriers meet complex configurations of up to 4m in length and thickness of up to 10mm.

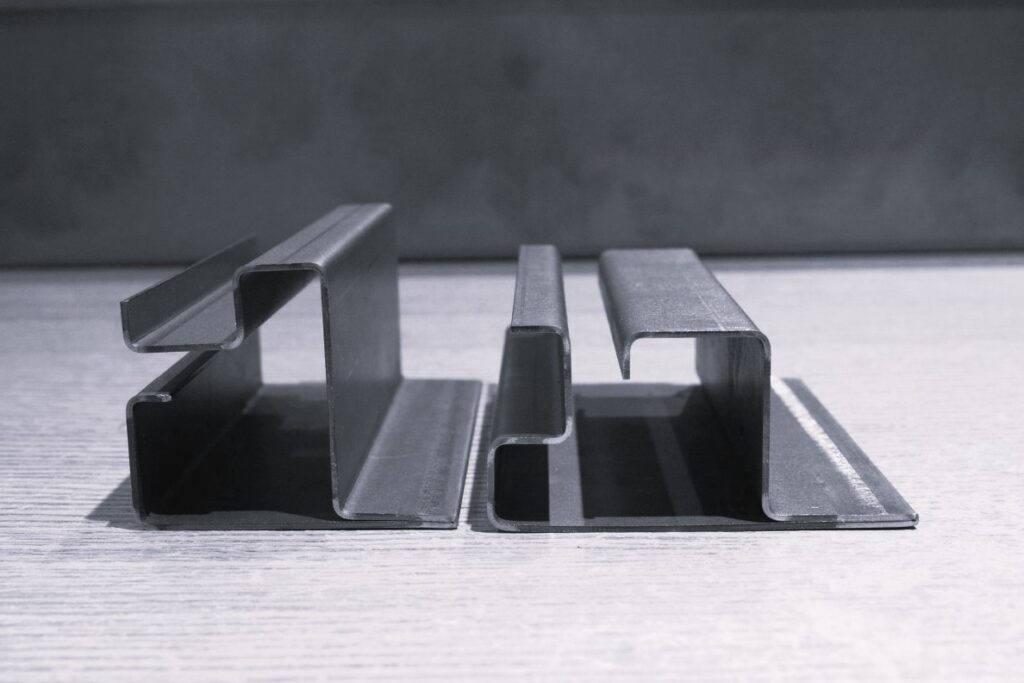

For the cylindrical shaping of plates we have rollers with the option to work on materials with length of up to 3m and thickness of up to 10mm. The capabilities of our rollers meet the needs of large industrial projects in Greece and abroad.

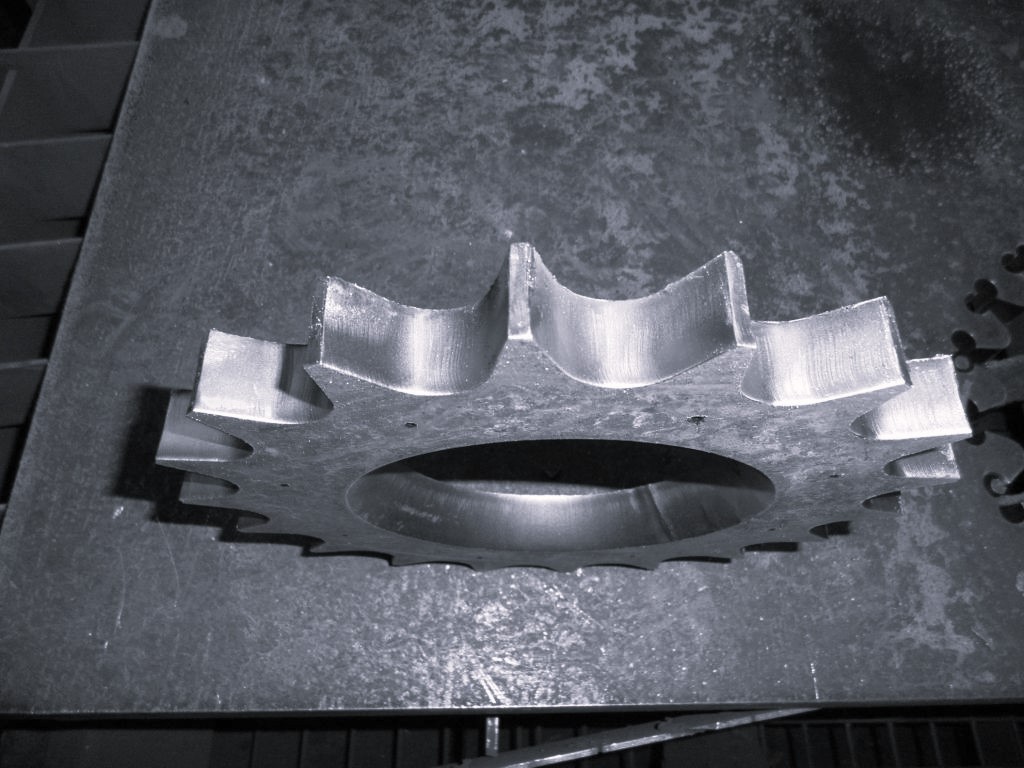

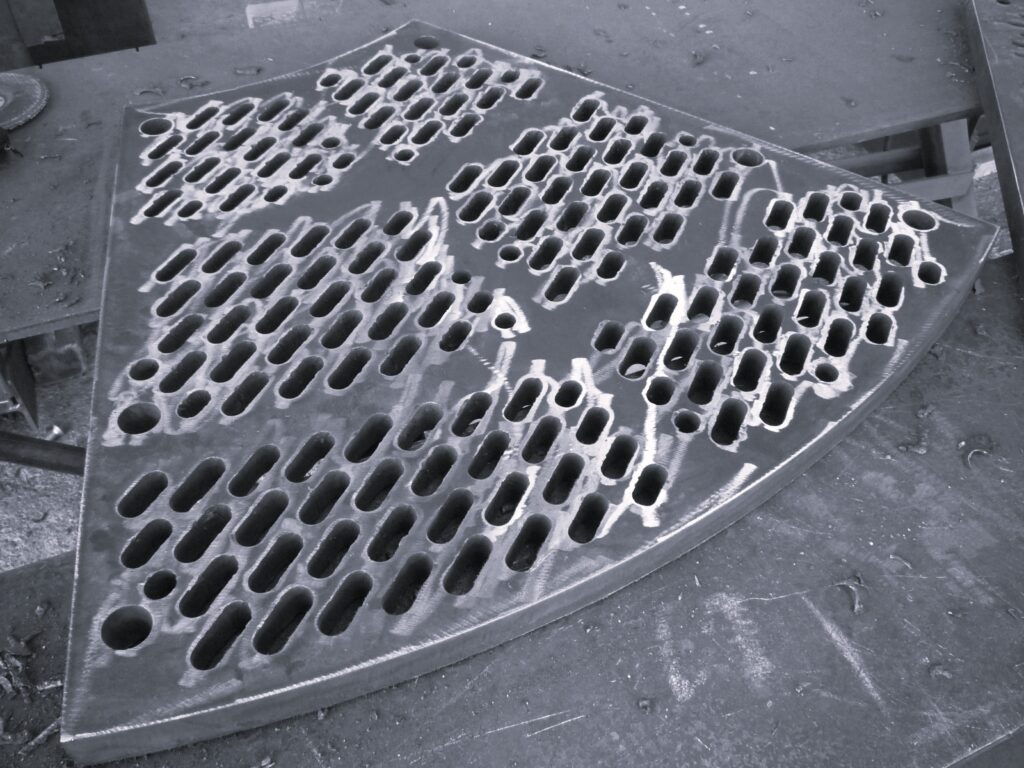

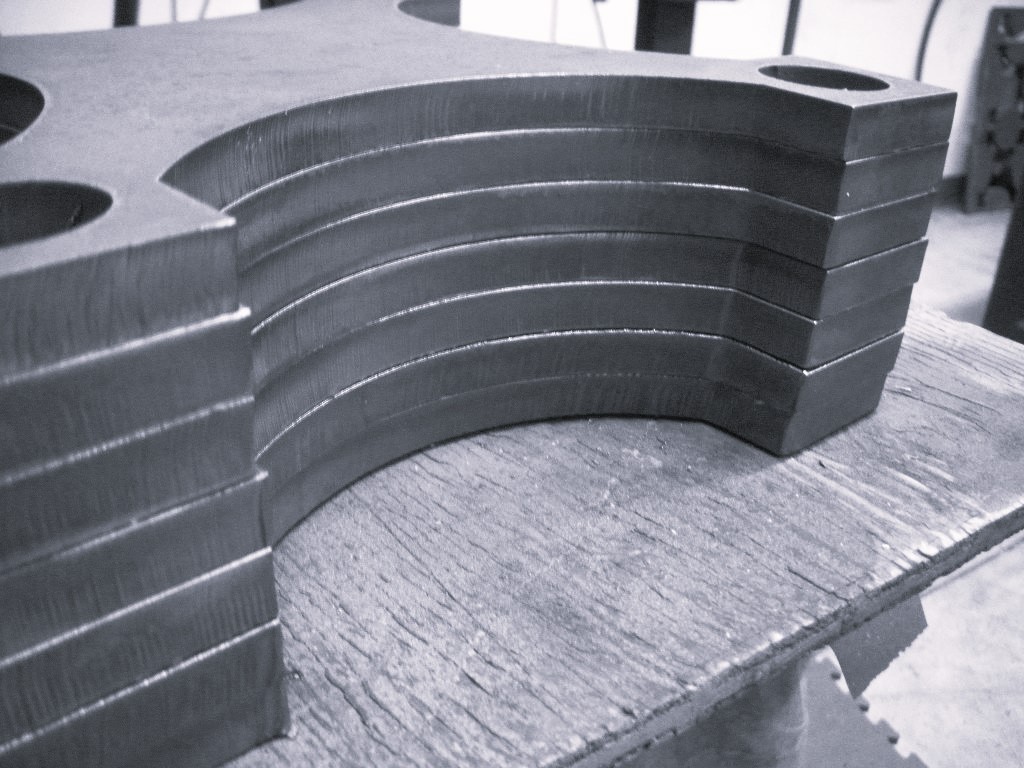

We have laser cutting machines as well as a state-of-the-art pantograph that provides top quality cuts regardless of the complexity of the products. These machines give us the ability to manufacture batches of many different types of products. We manufacture batches with almost zero unfinished product and in minimum production time, which reduces manufacturing costs. In addition, we respond to special cutting needs such as miter cutting and milling. Our cutting capacity now covers plates up to 2 x 4m in size and up to 100mm in thickness.

In addition, we have qualified and certified welders meeting our ultimate target of offering to the customer a complete end product.